Home People Research Publications Activities

Laser Scanners for Display and Imaging

We are developing both MEMS scanners and FR4 scanners for miniaturized display systems and imaging devices.

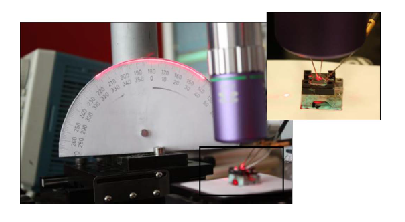

Mems Scanners

Fig. Arslan, A.; Brown, D.; Davis, W.O.; Holmstrom, S.; Gokce, S.K.; Urey, H.; ,

"Comb-

Miniaturized display and imaging systems increased the interest in MEMS scanners because MEMS scanners can meet the high resolution, low power consumption, and high scanning speed requirements in miniaturized display and imaging systems.

Our main goal in MEMS scanner projects is to investigate different scanner technologies

and scanning architectures to meet the compact form-

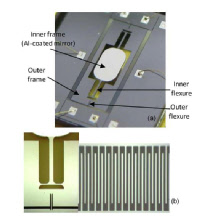

FR4 Scanners

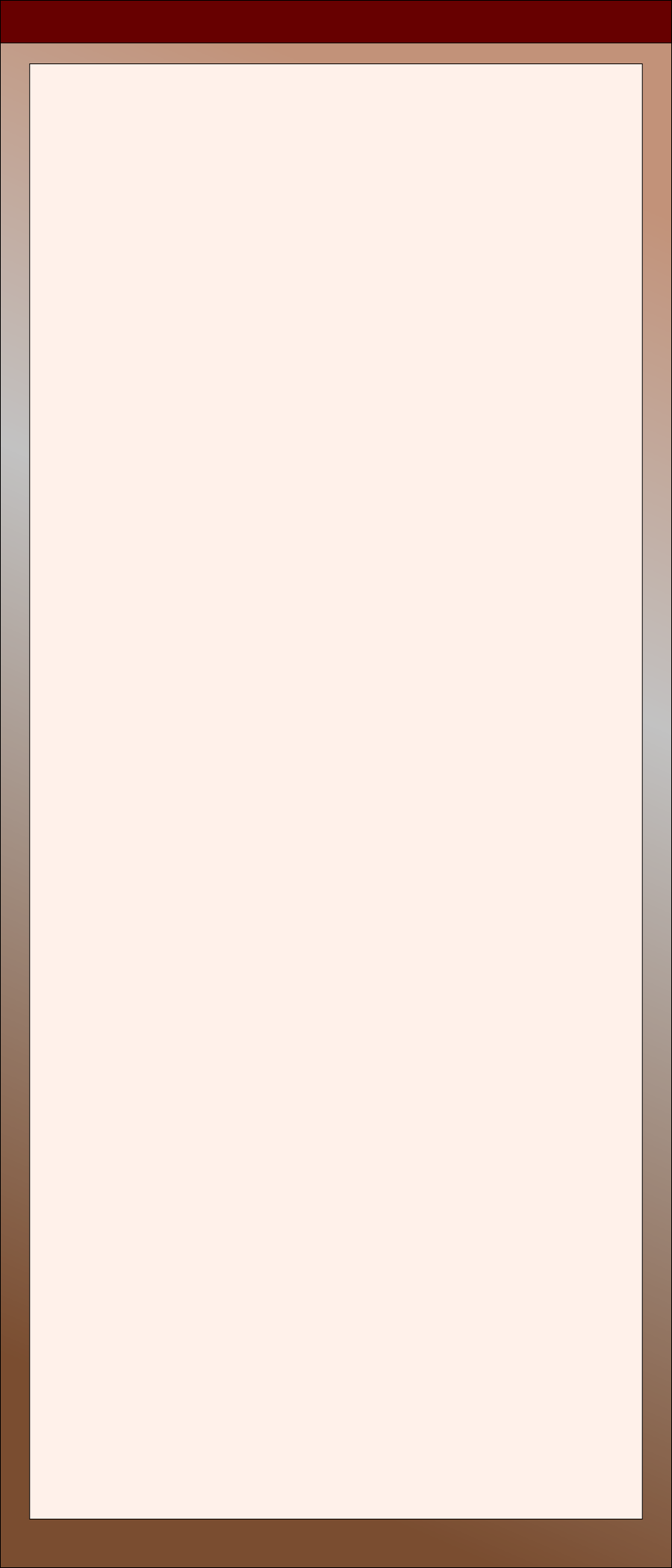

As an alternative to silicon MEMS, we developed new opto-

* FR4 Laser Scanner With Dynamic Focus

Serhan O. Isikman, Randy B. Sprague, and Hakan Urey,IEEE PHOTONICS

TECHNOLOGY LETTERS, VOL. 21, NO. 4, FEBRUARY 15, 2009

Fig. Picture of the PCB-

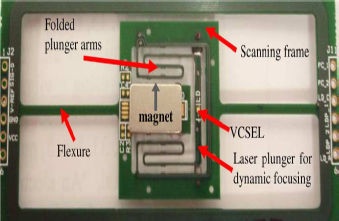

MEMS Stages for Microlens Array Scanners

Microelectromechanical systems (MEMS) have earlier been utilized for beam steering

with individual microlenses. The specific application motivating our work is high-

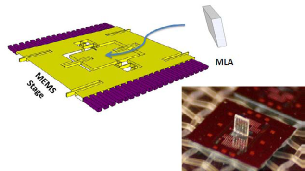

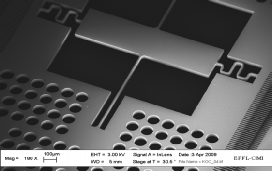

Fig. To the left an illustration of hybrid MLA integration and a MLA integrated MEMS stage. To the right, a SEM image of the empty stage

MEMS ve FR4 Tarayicilar Sunumu (In Turkish)